During deep drawing of metallic sheet having large grain size. Defects in Thermo Mechanical Processing of Metals.

Failure Analysis Of A Component With Orange Peel

During deep drawing the coarse grains with 100 microtexture can slip on the 112 slip system to form bulging and yields orange peelEstimated Reading Time.

. Orange Peel It occurs due to coarse grain structure of the drawn material. S Earing Anisotropy. During faulty heat treatment of steel.

Orange peel or surface roughness happens in coarse grain metals. Scratches Heavy scratches over the drawn cup may appear due to appearance of yield point phenomenon in the material. It is typically associated with sheet metal that has undergone a large amount of deformation such as during deep drawing.

Centre Burst or Chevron Cracking is common defect in extrusion process. Figure-Earing due to uneven drawing and part failure 3. Orange peel aluminum surface defect characteristics reflect.

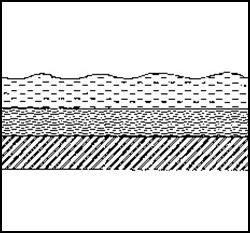

If the sheet metal is having a coarse grain structure near the punch corner radius the surface will be very rough and the defect is called Orange Peeling. Chen Jane Yao Hua-Kun Liu S. PRINCIPALLY ON SHEET METAL FORMING DEFECTS AS DESCRIBED IN THE ELEVENTH BIENNIAL CONGRESS OF THE INTERNATIONAL DEEP DRAWING RESEARCH GROUP IDDRG S.

135 orange peel the surface of the rolled piece is orange peel shaped and uneven. 195-211 1981 0020-740381J040195-17502000 Printed in Great Britain. Page 5 of 35 Issue Date.

Stretch strains are usually seen in yield point elongation of ductile materials. The diagrammatical representation of wrinkle is shown as. GHosH Department of Engineering.

Following are the defects that occur in metal during the drawing process. Q Orange peel large grain. 13052014 Defects Fault Finding CAUSES Blistering is caused by moisture or contamination under the paint due to.

Scratches Heavy scratches over the drawn cup may appear due to appearance of yield point phenomenon in the material. During deep drawing the coarse grains with 100 microtexture can slip on the 112 slip system to form bulging and yields orange peel defects while the coarse grains with 112. Cause of Orange Peel -.

December 29 2016. During deep drawing the coarse grains with 100 microtexture can slip on the 112 slip system to form bulging and yields orange peel. Grain structure should be refined before deep drawing.

Orange peel can occur when drawing raw material with grains that are too coarse. A related niobium microstructure can reveal poor smoothness and flatness of the deep drawn cup as each grain tends to deform separately and non- uniformly. It is called orange peel because the surface has the appearance of the surface of an orange.

R Stretch Strains Yield point elongation. This article discusses the causes of orange peel and engineering approaches for preventing it from occurring. During deep drawing the coarse grains with 100 microtexture can slip on the 112 slip system to form bulging and yields orange peel defects while the coarse grains with 112 orientation do not form the defect as the Schmid factor of 112 slip system in it equals zeroAuthor.

Orange peel is a certain kind of finish that may develop on painted and cast surfaces even screen protector. Q Orange peel large grain. They also extend to the surface of the cup.

Is also a phenomenon of surface roughening witnessed during deep drawing. Coating Defects Fault Finding Coating Defects car straight out of the oven into a cooler room. As a defect during metal casting welding.

Orange peel is a cosmetic defect associated with a rough surface appearance after forming a component. A very commonly occurring defect is the orange peel effect caused by coarse grain sizes. Orange peel extrusion defect analysis and quality control method.

Orange peel Plastic deformation such as stretching bending and drawing can develop rough surface which is usually termed as orange peel. Earing is also not the only grain-related deep drawing defect. Stretch strains are usually seen in yield point elongation of ductile materials.

R Stretch Strains Yield point elongation. Defects in deep drawing and their remedies Orange Peel It occurs due to coarse grain structure of the drawn material. It has been found that the orange peel defect in the st14 steel sheet was resulted from the local coarse grains which were produced during hot-rolling due to the critical deformation in dual-phase zone.

For deep-drawn materials it is sometimes necessary to limit the amount of deformation prior to final annealing in order to avoid earing. Grain structure should be refined before deep drawing. During extrusion of metal through a die.

14 dimensional defects 141 smaller transverse and longitudinal ribs continuous smaller phenomenon along the rolling direction. To eliminate Earing excessive deformation in deep drawing should be avoided. S Earing Anisotropy.

The texture resembles the surface of the skin of an orange hence the. Moisture absorption forms the substrate especially from putties and fillers before painting. Wrinkles are developed over the flange surface due to insufficient blank holder.

When sheet metal is not properly cooled the grains making up the metal tend to grow larger making deformities more obvious to the naked eye appearing like the texture of an orange peel - hence orange peel effect. Orange peel is a defect associated with a rough surface appearance after forming a component from sheet metal in deep drawing. An orange peel effect is observed.

Shankar Kumar PGWLF1850156 7 8. If the sheet metal is having a coarse grain structure near the punch corner radius the surface will be very rough and the defect is called Orange Peeling. The name roping is linked to.

It is called orange peel because the surface has the appearance of the surface of an orange. Earing is a defect that occurs due to uneven drawing as shown in figure. Orange peel is a cosmetic defect associated with a rough surface appearance after forming a component from sheet metal.

Sometimes orange peel surface shape after stretching aluminum wrinkles this is actually generated by the aluminum metal surface when the stress is greater than the base metal surface metal fragments grain crushing if it continues afterburner stress will be from the table and Lane until the matrix. Orange Peel - Industrial Metallurgists. Guoxiu Wang Stephen Bewlay Li Yang Jiazhao Wang Y.

Orange peel is a cosmetic defect most commonly found on sheet metal components after forming. Shankar Kumar PGWLF1850156 7 8.

Orange Peel Industrial Metallurgists

Orange Peel Industrial Metallurgists

Defect Of Deep Drawing Product Wrinkle A And Tear B Download Scientific Diagram

Surface Of Deep Drawing Product Without Orange Peel Defect A And Download Scientific Diagram

Orange Peel Effect Advice On Paint Defects Glasurit

Analysis Of Surface Orange Peel Of Automotive Aluminum Alloy Pipe Using Electron Backscatter Diffraction Ebsd Kne Materials Science

0 comments

Post a Comment